FITWELL ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FITWELL ENGINEERING COMPANY

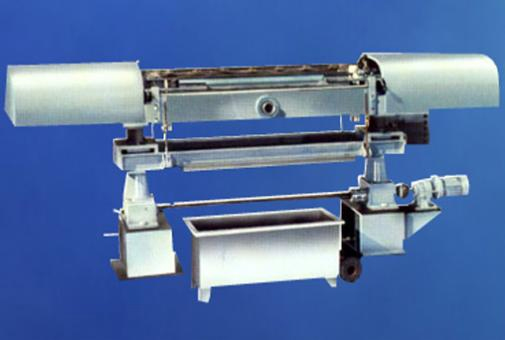

Brush Calendar

After coating on board surface, brushing is required for getting GLOSS on board surface. We manufacture Brush Calendar having Two Brush Rolls for brushing top side of board and one brush roll for back side of board. Brush Roll run's on two antifriction bearing and roll remains rigid in one position. For loading board against brush rolls, paper lead rolls are used and loading & unloading of paper lead rolls is done by pneumatic cylinders. There are adjusting screws with each pneumatic cylinder. We can level paper lead rolls as per board and adjust load on board with help of adjusting screws. These adjusting screws also guide bearing housings of paper lead roll.As complete machine is horizontal design, so paper feeding is very easy without any help of paper feeding rope carrier system. The machine is maintenance free and runs very smooth without vibrations. As machine is vibration free, so there are no patch types marking on paper surface. Overall machine is complete in all respect.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.